Long tube headers enhance engine performance through improved gas flow. Customized midpipes and strategic airflow management are key upgrades for optimal functionality. Integrating an extended midpipe requires precise measurement, secure connections, and testing to prevent leaks and backpressure, ensuring peak power and efficiency in high-performance exhaust systems.

Long tube headers, a powerful modification for automotive enthusiasts, demand tailored solutions. Standard midpipes often fall short, leading to reduced performance potential. This article delves into the unique requirements of long tube headers and highlights the benefits of customized midpipes. We provide a comprehensive guide on integrating extended midpipes, ensuring optimal engine performance and a seamless upgrade experience. Uncover why these custom components are essential for maximizing the capabilities of your vehicle’s exhaust system.

- Understanding Long Tube Headers' Unique Requirements

- Benefits of Customized Midpipes for Enhanced Performance

- Integrating Extended Midpipes: A Step-by-Step Guide

Understanding Long Tube Headers' Unique Requirements

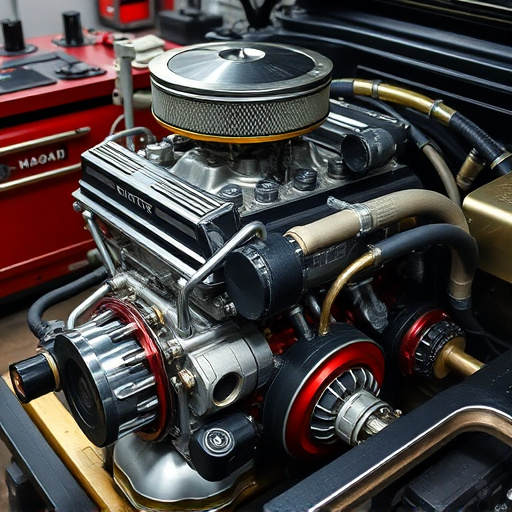

Long tube headers, a component integral to high-performance exhaust systems, present unique requirements distinct from their short-tube counterparts. Their elongated design facilitates more efficient gas flow, enabling better combustion and enhancing engine performance. This advanced configuration, however, necessitates specific considerations for optimal functionality.

The primary focus with long tube headers is ensuring proper airflow management. These headers often incorporate larger diameters and strategic bends to accommodate the extended flow paths. Integrating them seamlessly into the existing air intake systems is crucial, especially when matched with high-flow cold air intakes or performance brakes. This seamless integration ensures peak engine performance by facilitating a consistent and ample supply of cool, dense air, a key ingredient for efficient combustion.

Benefits of Customized Midpipes for Enhanced Performance

Customized midpipes are a game-changer for vehicles equipped with long tube headers. By tailoring the midpipe to fit the specific requirements of these high-performance systems, several key benefits can be realized. First and foremost, a custom design allows for improved airflow, which is crucial for maximizing the efficiency of long tube headers. This direct correlation between airflow and engine performance results in a more powerful and responsive vehicle, offering drivers an enhanced driving experience.

Additionally, tailored midpipes can significantly reduce backpressure within the exhaust system, especially when integrated with a cat-back exhaust or other modifications. This decrease in backpressure promotes efficient gas flow, further boosting engine power and improving overall efficiency. Customized muffler tips, designed to complement the long tube headers, also play a role by allowing for a more optimized sound signature, enhancing the vehicle’s overall personality without compromising performance.

Integrating Extended Midpipes: A Step-by-Step Guide

Integrating extended midpipes into a long tube header setup is a precise task that requires careful planning and execution for optimal performance. Here’s a step-by-step guide to ensure a smooth transition:

1. Measure and Cut: Begin by accurately measuring the existing header layout, including the distance between the engine block and the exhaust tips. Cut the midpipe to length, ensuring a clean and precise fit. This step demands precision to align with the header’s geometry.

2. Prepare the End Connections: Clean the ends of the extended midpipe and the headers to remove any debris or corrosion. Use thread tape or a suitable sealer to prevent leaks at the connections. Align the midpipe with the header flanges, ensuring they are level and secure with proper torque. This crucial step guarantees efficient gas flow and prevents potential damage.

3. Install Exhaust Components: Once the midpipe is in place, attach the muffler tips or other high-performance parts, such as performance headers. Ensure these components are securely fastened, allowing for proper exhaust gas dissipation while maintaining stability during operation.

4. Test and Fine-Tune: After assembly, test the system to ensure there are no leaks and that the exhaust flows smoothly. Adjust as necessary, checking the alignment of the extended midpipe with the header to guarantee optimal performance and reduce backpressure.

Long tube headers, while offering superior performance and flow characteristics, necessitate custom or extended midpipes for optimal efficiency. Customized midpipes enhance engine performance by ensuring smooth air flow, enabling better combustion, and ultimately boosting power output. Integrating these components requires careful planning and following a step-by-step guide to ensure a seamless fit. For enthusiasts seeking to unlock the full potential of their vehicles, embracing custom solutions like extended midpipes is key to achieving superior results with long tube headers.