Long tube headers are crucial components in high-performance automotive exhaust systems, enhancing gas exchange, boosting power output, reducing backpressure, and improving engine performance. Proper welding techniques using TIG or MIG methods, clean surfaces, and high-quality materials ensure leak-free assembly, optimize gas flow, prevent fluid leaks, and enhance vehicle stability. This step-by-step guide focuses on achieving a seamless, smooth finish for efficient vehicle operation and reliable performance.

Proper welding is paramount for successful long tube header installations, ensuring optimal engine performance and reliability. Long tube headers, known for their enhanced cooling capacity and reduced backpressure, demand precise welds to prevent leaks. This article delves into the significance of these components, highlights critical welding techniques, and provides a step-by-step guide to achieving a leak-free setup, ultimately maximizing the benefits of long tube headers in your engine build.

- Understanding Long Tube Headers and Their Significance

- The Importance of Proper Welding Techniques

- Leak-Free Setup: Step-by-Step Guide to Ensuring Success

Understanding Long Tube Headers and Their Significance

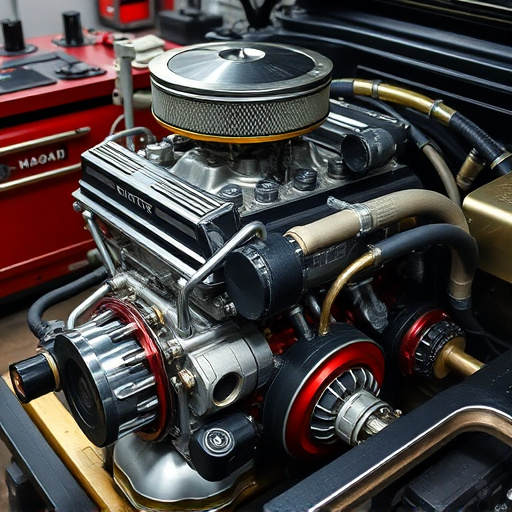

Long tube headers are a critical component in many automotive exhaust systems, especially those designed for high-performance applications like modified vehicles and race cars. These components serve as the backbone of an efficient and powerful exhaust setup, connecting multiple tubes to facilitate the flow of exhaust gases. The significance of long tube headers lies in their ability to provide a smooth transition for exhaust gases from the engine cylinders, enhancing overall system performance.

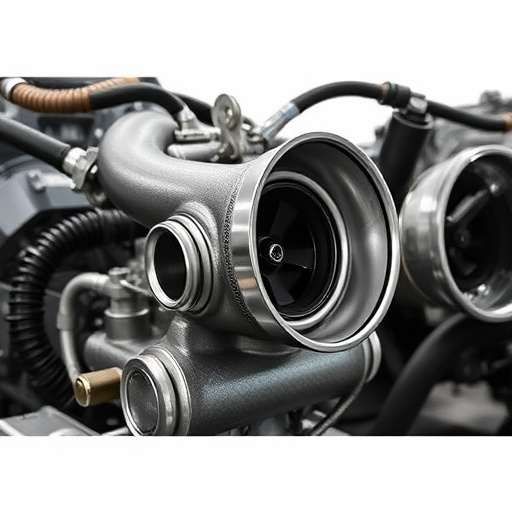

By incorporating long tube headers, vehicles equipped with high-performance air filters or cold air intakes can achieve better gas exchange and increased power output. This is because these headers enable more efficient turbulence within the tubes, allowing exhaust gases to quickly and smoothly exit the combustion chamber. As a result, the entire exhaust system operates at reduced backpressure, leading to improved engine performance and potentially higher fuel efficiency in some cases.

The Importance of Proper Welding Techniques

Proper welding techniques are paramount when setting up long tube headers for optimal performance and longevity. In the realm of automotive engineering, these headers play a crucial role in enhancing engine efficiency by facilitating efficient gas flow, which is particularly essential for high-performance vehicles. The meticulous application of welding ensures that every joint and seam is sealed tightly, creating a leak-free system. This prevents not only the loss of valuable cooling fluids but also ensures the reliable operation of intake components and suspension kits, thereby enhancing overall vehicle stability.

Moreover, the precision involved in proper welding goes beyond mere functionality; it contributes to the aesthetic appeal of the final product. In the intricate landscape of a vehicle’s engine bay, flawlessly executed welds add to the overall sophistication and polish of the setup, including suspension components. This attention to detail not only captivates the eye but also instills confidence in the quality and durability of the long tube headers, ensuring that every drive is as smooth and efficient as intended.

Leak-Free Setup: Step-by-Step Guide to Ensuring Success

Leak-Free Setup: Step-by-Step Guide to Ensuring Success

Proper welding is paramount when assembling long tube headers for optimal performance and reliability. Begin by ensuring a clean, oil-free surface on all components. Use high-quality welding materials suitable for automotive applications, especially when integrating with air intake systems or exhaust systems. Precise weld techniques, such as TIG or MIG welding, offer better control, resulting in stronger, more consistent connections.

Follow a systematic approach: first, align the long tube headers perfectly; then, apply a bead of weld along the joint, ensuring complete coverage. Allow the weld to cool gradually, preventing sudden temperature changes that could cause warping. Inspect the weld for any cracks or inconsistencies using a high-powered magnifying glass. If needed, re-weld and sand for a smooth finish. This meticulous process guarantees a leak-free setup, crucial for the efficient operation of brake components and overall vehicle performance.

Proper welding techniques are paramount for achieving a leak-free setup with long tube headers, ensuring optimal performance and reliability. By following a meticulous step-by-step guide, one can navigate the process effectively, fortifying against potential leaks. Investing in robust welding practices not only guarantees the integrity of the long tube headers but also underpins the overall success of any automotive cooling system, enhancing both efficiency and longevity.