Long tube headers are high-performance exhaust systems engineered for optimal engine output at high RPMs. Their elongated tubing design enhances gas flow, decreases backpressure, and improves combustion efficiency. Integrating with air intake systems, they ensure efficient oxygen supply to the engine. Many models incorporate noise-reducing mufflers while maintaining flow efficiency. Through precise engineering, these headers balance cooling capabilities, airflow optimization, and heat distribution for increased power output and improved throttle response. Pairing them with advanced intake components significantly boosts vehicle performance in high-RPM applications.

Long tube headers, a relative newcomer to the automotive performance scene, are making waves in high-RPM applications. This innovative design offers significant advantages over traditional header setups, optimizing exhaust flow and enhancing engine performance at elevated revolutions per minute (RPM). Understanding the basic concept behind long tube headers is key to unlocking their potential for improved horsepower, torque, and throttle response. In this article, we’ll explore these benefits and delve into the designing and optimizing processes for maximum high-RPM performance.

- Understanding Long Tube Headers: The Basic Concept

- Advantages of Long Tube Headers for High RPM Applications

- Designing and Optimizing Long Tube Headers for Maximum Performance

Understanding Long Tube Headers: The Basic Concept

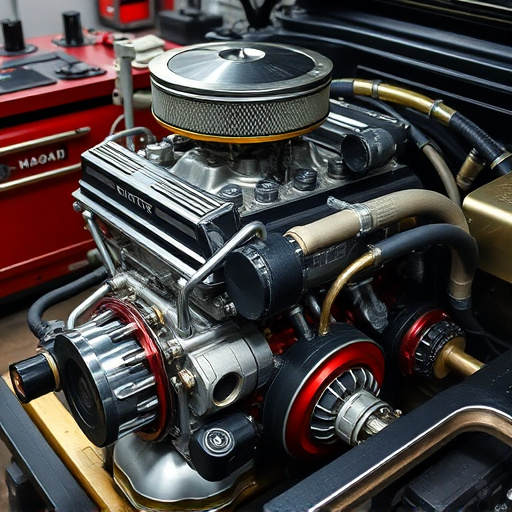

Long tube headers are designed to enhance performance in high-RPM engines by optimizing airflow and gas flow within the exhaust system. Unlike short tube headers that collect gases from a smaller number of cylinders, long tube headers feature longer, more intricate paths for exhaust gases to follow. This design allows for better gas flow, reduced backpressure, and improved combustion efficiency, all crucial factors in achieving higher engine RPMs.

By extending the length of the tubes, these headers also serve as part of a sophisticated air intake system, enabling a more efficient transfer of fresh air into the engine. This integration with the air intake systems ensures that the engine receives ample oxygen, further boosting its performance potential. Moreover, long tube headers often incorporate exhaust mufflers designed to reduce noise while maintaining flow efficiency, contributing to both performance and user experience in high-RPM applications.

Advantages of Long Tube Headers for High RPM Applications

Long tube headers are a popular choice for high RPM applications due to their numerous advantages. Firstly, they offer enhanced cooling capabilities, ensuring optimal engine temperatures even under intense conditions. This is particularly beneficial for vehicles designed for performance, where pushing the engine to its limits is common. The extended tubing provides a larger volume of air, allowing for better airflow and more efficient combustion, which directly contributes to increased power output.

Moreover, long tube headers often come with advanced design features like optimized exhaust gas flow paths and improved heat distribution. These designs can reduce backpressure in the exhaust system, thereby enhancing engine breathability. When combined with high-flow air filter kits and efficient exhaust systems, long tube headers can significantly boost vehicle performance at high revolutions per minute (RPM).

Designing and Optimizing Long Tube Headers for Maximum Performance

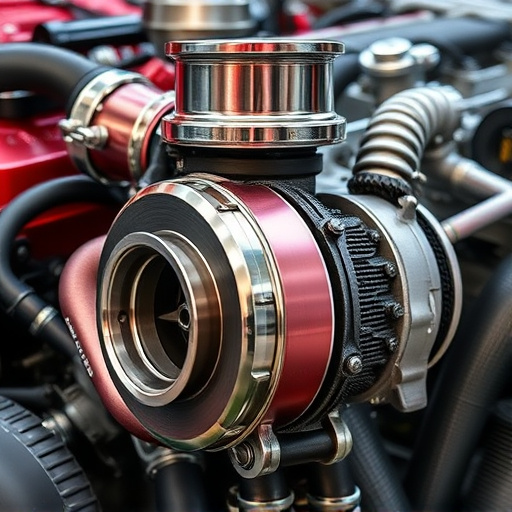

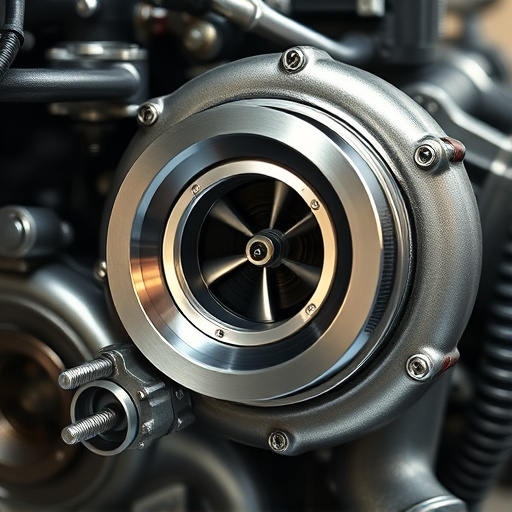

Designing long tube headers for high RPM performance involves a delicate balance between engineering precision and aerodynamic efficiency. These specialized exhaust manifolds, characterized by their elongated tubes connecting multiple combustion chambers, are tailored to enhance vehicle performance at elevated engine revolutions. Engineers must carefully consider factors such as flow dynamics, heat transfer, and material selection to optimize the headers’ functionality.

By meticulously crafting each component—from the tube diameter and bend angles to the placement of collectors—designers can minimize restrictions in the exhaust gas path, ensuring smoother flow and quicker evacuation of gases. This, in turn, enhances engine breathing, resulting in improved throttle response and power output. Furthermore, integrating advanced intake components that complement the long tube headers is crucial for achieving peak performance, as it allows the engine to draw in more air, contributing to a healthier combustion process and overall vehicle performance.

Long tube headers, with their intricate design and optimized flow, are a game-changer for high-RPM performance. By strategically routing exhaust gases and enhancing heat transfer, these headers provide significant advantages in power output and efficiency. For enthusiasts seeking to unlock the full potential of their vehicles, especially in racing or high-performance driving, understanding and integrating long tube headers can lead to exceptional results. This specialized component is a key element in crafting a high-RPM machine that delivers both power and reliability.